2010–2018 PET-pullojen tuotantolinja 14 000 bph SIPA-pullonpuhallislaitteilla ja VETRO-ilmakuljetinjärjestelmällä

: 10722025

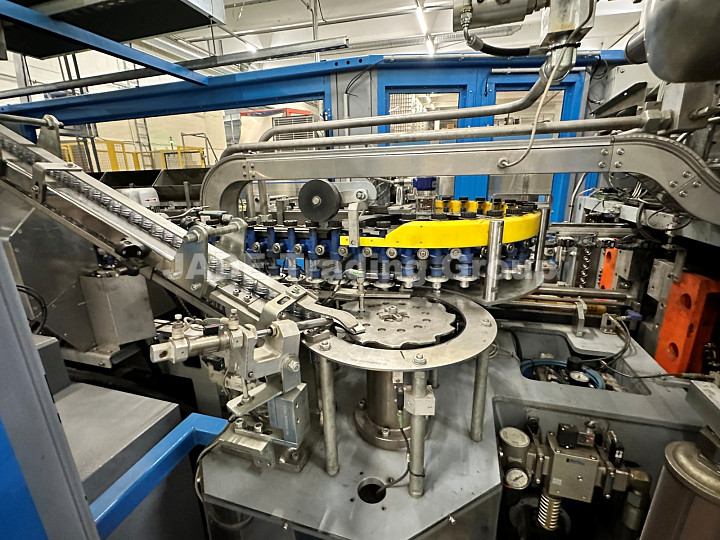

Täysautomaattinen linja PET Pullojen valmistamiseen ja kuljettamiseen täyttölaitteelle. Linja koostuu kahdesta rinnakkain asennetusta SIPA SFL 4-pesäisestä lineaarisesta PET-pullonpuhallus koneesta, joissa on integroidut painovoimaiset preformien syöttöjärjestelmät ja VETRO-ilmakuljetinjärjestelmästä PET-pullojen kuljettamiseksi puhalluskoneista täyttölaitteeseen.

Technical Details

- Valmistaja SIPA and VETRO

- Valmistajan tyyppimerkintä PET Bottle Production Line

- Valmistusvuosi 2010

- Kapasiteetti 14000 bph

- Tuoteryhmä PET Bottle Production from Preforms and Air Transportation of Bottles

PET Bottle Production Line 14000 bph with SIPA Blow Moulders and VETRO Air Conveyor System

Fully automatic line consists of two in parallel mounted SIPA SFL 4-cavity linear PET stretch-blow moulding machines with integrated preform gravity feeding systems and VETRO air conveyor system for PET bottles from blow moulders to a filler. Double blow moulding machines give a great flexibility in production capacity and efficiency. Machines have been serviced annually according to manufacturers’ instructions, are still in operation and in perfect condition. All machines are CE certified and have complete original documentation

List of main equipment

- Blow Moulder SIPA SFL 4/4 OLO 12, year 2010, operating hours approx. 21430, with hopper, preform tilter, preform elevator, linear preform unscrambler and Chiller Clint THA/K/SP 151 CC (R410A), year 2016

- Blow Moulder SIPA SFL 4/4 OLO 254, year 2015, operating hours approx. 10600, with hopper, preform tilter, preform elevator, linear preform unscrambler and Chiller M.T.A TAE 051 (R410A)

- One set of 1500 ml round bottle moulds for both machines

- Air conveyors Vetro Mechnica, automatic bottle size adjustment, automatic feeding from two blowers to one filler, with own Siemens PLC control panel, year 2018. Suitable for PET bottles with diameter from 35mm to 94 mm, and height up to 321 mm. Total length of air conveyor is 40+ meters, it has 8 numbers of transport fans with total installed power of 17.6 kW / 400 V / 50 Hz.

Technical Characteristics of both SIPA Blow Moulders

- Model SFL 4/4 OLO linear 4-cavity stretch blow machine with energy saving system

- Full load electric power rating is 123 kW / machine, 400 V / 50/60 Hz

- Required pressurized air at 30 bar is 195 Nm3/h for one machine

- Manufacturing years 2010 and 2015, running hours 21430 and 10600 respectively

- Bottle sizes produced 950 ml and 1500ml, neck format PCO 1881 (short cap)

- Output capacity up to 1,800 bottles/hour/cavity at 500 ml

- Machine is fully electric, two-stage linear stretch-blow moulding system

- Heating system has modular two oven system with 10 lamps, equipped with laminar flow ventilation to prevent neck crystallization.

- Stretching mechanism is servo-driven for precise control

- Control Interface has a touchscreen graphical interface for machine control, process parameters, diagnostics, and maintenance procedures

- Changeover from one type bottle to another type can be made in 30 minutes with one operator

- Low maintenance design with self-lubricating components and lubrication-free oven chain

Whatch a video of SIPA in operation